-

StefanChúng tôi rất vui khi được hợp tác với ERBIWA, và cảm ơn sự hỗ trợ của bạn cho từng dự án của chúng tôi.

StefanChúng tôi rất vui khi được hợp tác với ERBIWA, và cảm ơn sự hỗ trợ của bạn cho từng dự án của chúng tôi. -

RobertNó rất tốt đẹp để nhận được các khuôn mẫu với chất lượng hig và dịch vụ cao cấp, nhưng giá cả thuận lợi. Chúng tôi sẽ tiếp tục hợp tác với bạn trong các dự án trong tương lai.

RobertNó rất tốt đẹp để nhận được các khuôn mẫu với chất lượng hig và dịch vụ cao cấp, nhưng giá cả thuận lợi. Chúng tôi sẽ tiếp tục hợp tác với bạn trong các dự án trong tương lai. -

CarlosBạn là một đội ngũ năng động và mạnh mẽ, tôi đã nhìn thấy tương lai của sản xuất Trung Quốc từ tất cả các bạn.

CarlosBạn là một đội ngũ năng động và mạnh mẽ, tôi đã nhìn thấy tương lai của sản xuất Trung Quốc từ tất cả các bạn.

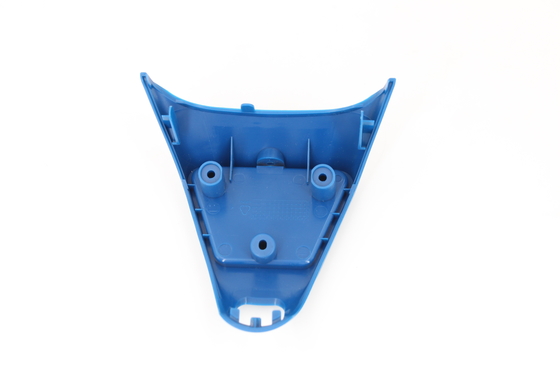

Các thành phần khuôn nhựa chính xác cho đường dây điện tim phổ quát và EKG 7 kim

| Nguồn gốc | Quảng Đông, Trung Quốc |

|---|---|

| Hàng hiệu | Erbiwa Mould |

| Chứng nhận | ISO 9001: 2015 IATF 16949: 2016 |

| Số lượng đặt hàng tối thiểu | 1 bộ |

| Giá bán | negotiable |

| chi tiết đóng gói | gói tiêu chuẩn xuất khẩu |

| Thời gian giao hàng | 30-60 ngày |

| Điều khoản thanh toán | TT, L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Khả năng cung cấp | 1 bộ mỗi tháng |

Liên hệ với tôi để có mẫu và phiếu giảm giá miễn phí.

Whatsapp:0086 18588475571

wechat: 0086 18588475571

Ứng dụng trò chuyện: sales10@aixton.com

Nếu bạn có bất kỳ mối quan tâm nào, chúng tôi cung cấp trợ giúp trực tuyến 24 giờ.

x| Loại | Bộ kết nối điện tử | Chức năng sản phẩm | Kết nối các dây khác nhau |

|---|---|---|---|

| vật liệu khuôn | Thép | Chất liệu sản phẩm | ABS+PC |

| Lỗ | đa | tuổi thọ khuôn | 300.000-1.000.000 bức ảnh |

| đế khuôn | LKM, HASCO, DME hoặc theo yêu cầu của bạn | ||

| Làm nổi bật | Các thành phần khuôn nhựa chính xác,7 ECG kim Các thành phần khuôn nhựa |

||

Bộ kết nối điện cho đường dây điện tim phổ quát với 7 kim điện tâm

Mô tả sản phẩm

| Dịch vụ của chúng tôi | Sản xuất khuôn, chế tạo phun, sản xuất nén, lắp ráp sản phẩm, nguyên mẫu CAD,Pro-E,UG |

| Số khoang | Một khoang, nhiều khoang, khuôn gia đình |

| Các bộ phận tiêu chuẩn khuôn | DME,HASCO hoặc theo yêu cầu của khách hàng |

| Hệ thống chạy | Người chạy nóng, người chạy lạnh |

| Điều trị bề mặt | Sơn, kết cấu, ăn mòn từ |

| Quá trình chính | CNC,EDM,cắt dây điện cực,đổ hố,màn xoắn,nhiều xử lý bề mặt,thiết bị,cảnh thử |

| Vật liệu phụ tùng | ABS,PP,PC,PVC,TPU,SMC,BMC vv |

| Đảm bảo chất lượng | ISO 9001; IATF 16949 |

Những lợi thế và dịch vụ mà bạn đã liệt kê làm nổi bật cách tiếp cận toàn diện và tập trung vào khách hàng mà công ty bạn áp dụng đối với việc đúc phun phụ tùng ô tô.

Ưu điểm:

1Chuyên môn:Nhóm của bạn bao gồm các nhà thiết kế công cụ có kinh nghiệm có khả năng xử lý các dự án phức tạp.

2- Sự linh hoạt về vật liệu và chuyển đổi nhanh chóng:Bạn cung cấp một loạt các vật liệu và cam kết thời gian giao hàng nhanh chóng.

3. Công cụ chất lượng cao:Sử dụng thép tốt đảm bảo độ bền và tuổi thọ lâu dài của khuôn.

4Dịch vụ tích hợp:Cung cấp một gói dịch vụ đầy đủ bao gồm thiết kế khuôn, đúc phun, sơn, in màn hình, lắp ráp và hỗ trợ sau bán hàng.

5Thiết bị tiên tiến:Có máy móc hiện đại cho cả quá trình tạo khuôn và đúc phun.

6Khả năng tùy chỉnh:Cung cấp dịch vụ OEM (Nhà sản xuất thiết bị gốc) và ODM (Người sản xuất thiết kế gốc).

7Thiết kế khuôn tùy chỉnh:Thiết kế khuôn phù hợp dựa trên thông số kỹ thuật của khách hàng và chuyên môn trong ngành.

8Các lựa chọn vật liệu:Cung cấp các vật liệu nhựa khác nhau phù hợp với các ứng dụng khác nhau.

9. Tùy chỉnh màu sắc:Có thể phù hợp với bất kỳ màu nào theo yêu cầu của khách hàng.

10. Tuân thủ & Tiêu chuẩn:Tuân thủ các tiêu chuẩn an toàn và môi trường có liên quan như RoHS, UL và các tiêu chuẩn khác.

11Chứng chỉ:Có chứng chỉ ISO9001 và ISO14001 đảm bảo quản lý chất lượng và môi trường.

12Kiểm soát chất lượng:Thực hiện các tiêu chuẩn kiểm soát chất lượng nghiêm ngặt kiểu Nhật Bản và tiêu chuẩn kiểm tra châu Âu.

13- Phạm vi dịch vụ:Bao gồm một loạt các dịch vụ từ chế tạo khuôn đến lắp ráp sản phẩm cuối cùng.

14Hiệu quả chi phí và hiệu quả phân phối:Cung cấp giá cả cạnh tranh và lịch trình giao hàng đáng tin cậy.

Dịch vụ:

1- Truyền thông đáp ứng:Cam kết trả lời tất cả các câu hỏi ngay lập tức.

2Nhân viên chuyên nghiệp:Nhân viên được đào tạo tốt, nói tiếng Anh trôi chảy để hỗ trợ khách hàng quốc tế.

3Giá cả cạnh tranh:Cung cấp giá cạnh tranh mà không ảnh hưởng đến chất lượng.

4Đội quản lý dự án:Có một nhóm chuyên dụng để quản lý các dự án hiệu quả.

5Các giải pháp tùy chỉnh:Cung cấp các giải pháp khuôn phù hợp dựa trên nhu cầu cụ thể của khách hàng.

6Quá trình chấp thuận:Cung cấp các bản vẽ khuôn chi tiết trong định dạng 2D và 3D để khách hàng chấp thuận trước khi sản xuất.

7- Vật liệu hỗ trợ:Cung cấp phụ tùng thay thế, hướng dẫn sử dụng và bản sao kỹ thuật số của bản vẽ khuôn.

Thông tin bổ sung:

Dịch vụ OEM:Cung cấp các tùy chọn tùy chỉnh bao gồm bao bì, thương hiệu và nhãn hiệu.

Số lượng đặt hàng tối thiểu (MOQ):Thông thường yêu cầu MOQ 1000 đơn vị cho tùy chỉnh.

Cách tiếp cận toàn diện này chứng minh cam kết của công ty bạn để cung cấp các bộ phận ô tô chất lượng cao thông qua đúc phun trong khi cung cấp tính linh hoạt, tùy chỉnh,và dịch vụ khách hàng tuyệt vờiNó cũng cho thấy sự cống hiến của bạn để đáp ứng và vượt quá các tiêu chuẩn của ngành và mong đợi của khách hàng.

![]()

![]()

![]()

![]()

![]()

![]()